Machines and equipment are arguably some of the most essential tools for any business in the construction industry. Without your fleet, non-powered, and powered equipment, your company won’t be able to fulfill rental or construction jobs.

Equipment tracking devices for tools are a great way to ensure that your fleet does not experience any downtime. Keeping equipment downtime to a minimum will ensure that you can be efficient and effective, minimizing lost time and inflated budgets.

Theft

Unfortunately, one of the reasons for downtime is an increase in theft. According to the National Insurance Crime Bureau (NICB), there are almost 1000 reported cases of commercial theft every month in the US.

Unauthorized usage

When your equipment is being used outside of contract hours on unknown job sites by operators who may not be licensed to do so, you won’t know the actual usage of your machines. This leads to faster depreciation and an increase in unforeseen breakdowns.

Unforeseen machine errors

If you operate in the construction industry, you will most likely experience equipment breakdowns. Most errors will most likely be unforeseen and can end up being costly.

Theft, unauthorized usage, and unforeseen machine errors are aspects of the construction industry that many have accepted as the only reality. Yet, with improvements in tracking technology, we can move away from the past truth. Today, thanks to advances in network availability, trackers can do much more than previously possible.

In a snapshot, GPS trackers can allow you to:

GPS tracking technology allows you and your customer to see the location of your machines without having to be nearby. Many companies value knowing the location of their machines so they can get an overview of their equipment, using GPS tracking devices to unlock that value.

Apart from knowing the location of your machines, a GPS tracking solution can enable you to set up perimeters that limit how much your heavy equipment can travel within a designated area. GPS trackers for tools, like your non-powered assets, can also be valuable, as your smaller equipment is easy to lose track of. Whether your equipment is non-powered or battery-powered, a GPS tracking device can unlock location information that could make your company more efficient.

GPS tracking devices are great for locating your assets if you’re on busy construction sites or if you’ve lost your equipment. But, GPS trackers for tools and other assets are also advantageous in the case of theft protection.

Using trackers on your heavy equipment, smaller tools, and even trailers can increase the recovery rate in case of theft. A GPS tracking device is a helpful tool that can potentially save you hundreds of thousands a year.

Construction equipment, assets, and tools are essential but can incur many costs when running a business in the construction industry. A company in the industry can have multiple assets, and keeping track of all the maintenance schedules, among other things, with pen and paper, can come with risks that lead to quick depreciation and poor machine health.

With tracking devices, you get access to multiple machine features that could help you improve how you utilize your machines.

Track your equipment to be able to:

If you are in the rental or construction industry, you can use this information gathered by our GPS trackers for tools and equipment to improve customer service by preventing breakdowns before they occur and understanding how the equipment is best utilized.

An equipment tracker is not just for location tracking, although that is a definite benefit. Equipment tracking is also a critical aspect of ensuring the appropriate usage of your machines. Whether you are sharing machines on a construction site or renting out machines to a customer, you want to enforce the contract you have agreed upon.

Asset tracking allows you to do that because you can track engine hours and asset utilization. If you have agreed to a 45-hour utilization contract, you can ensure that this is upheld by tracking how many hours the machine has been utilized. You can also make sure the equipment is being used safely by looking at discrepancies in speed, weight load, etc. Equipment tracking gives you a glimpse into your equipment.

By enforcing the proper utilization of your machines you might also experience insurance benefits. If you can document that your equipment is being used responsibly, you could get lower insurance costs.The benefits of enforcing proper utilization:

This is becoming an increasingly important benefit of using an equipment tracker on your assets. As the industry takes steps towards sustainability, greater efficiency, and social responsibility, you need to document the impact of your business.

Sustainability

With an asset tracker, you can gather the data necessary to do the calculations that give insight into your carbon footprint. This could be a combination of the fuel used, machine hours, and location.

Legislative reporting

On the legislative side, governments have begun asking for more documentation about how equipment is being utilized. As mentioned previously, using a GPS tracker for your assets can enable you to gather this information.

Using asset tracking and GPS trackers for tools and equipment has many benefits, but it can be hard to get started. At Trackunit, we strive to give our customers access to valuable data through high-quality trackers that provide you with the information you need, regardless of equipment size or if it is powered or non-powered.

Finding the right equipment tracker for your needs

Equipment tracking of heavy equipment, like bulldozers and dumpers, to smaller equipment and accessories like plate vibrators and shovels is essential for any business in the construction industry. While you can track each piece of equipment or item in your depot, the devices you’ll need could differ based on your needs.

Tracking device for battery-powered equipment

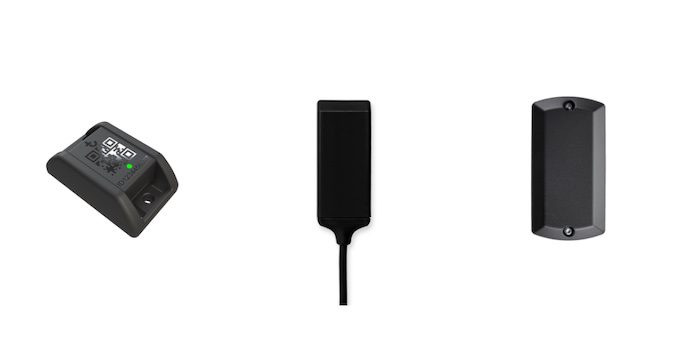

The Trackunit Raw is the equipment tracking device that we recommend for powered, heavy equipment. Using this hardware on your entire fleet of heavy construction equipment can unlock significant value.

With GPS tracking, you’ll be able to identify the location of your assets from any remote location. This will allow you to get an overview of what machines are being used where. You can also see what is available for use. You can even increase the chance of recovery of your stolen equipment, as the unit is not reliant on its own network and rather uses large, well-established networks.

With the latest edition of the Trackunit Raw, the TU600, you get much more than a GPS tracking device. The newest hardware allows you to get rich information about your machine that can inspect data like:

With such deep insight into your construction equipment, your business can start managing your fleet more effectively.

Here’s a quick look at the features of Trackunit Raw

Our Raw devices are all made to last. The usual lifespan of our trackers is around 5+ years. But with more than 300,000 connected machines around the world, we’ve seen many last over 10 years. Each unit is Bluetooth 5.0 enabled to ensure optimum range capabilities. Each device has a backup battery which has a lifespan of 2-3 weeks if uncoupled from its power source. Get the Trackunit Raw specifications here.

Tracking devices for non-powered equipment

Putting a tracker on your non-powered equipment is just as vital as your large, powered equipment to build a complete fleet overview. Trackunit can provide two different options for tracking non-powered equipment.

You can use either the Spot, which is a battery-powered GPS tracking device, that has its own signal capabilities. Or you can use the Trackunit Kin, which is a Bluetooth tracking device.

Spot – A tracker for your non-powered assets

Our Spot tracking device is catered to your medium-sized assets that don’t have a built-in power source. It’s compact and easy to install, so there’s no hassle in getting started.

This hardware does not have as many data collection capabilities as the Trackunit Raw. But it can be beneficial to track utilization or in case of theft. The tracker has a built-in sensor that detects movement and can tell you when your asset is being used. Our Spot device also has GPS tracking capabilities which can help increase the chance of recovery of your stolen assets.

Like Trackunit Raw, our Spot solution has its own network capabilities, and therefore, it will relay data to you in intervals that you can set up yourself. Read more about Spot here.

Trackunit Kin – A Bluetooth tracker with a long battery life

The Kin is the latest addition to Trackunit’s hardware family. It is a small compact device that completes the overview of your entire fleet. You can put the Kin on any asset that you own, but it is primarily used on smaller, non-powered assets like; trailers, machine shovels, plate vibrators, etc. that can benefit from GPS trackers for tools and equipment.

The main difference between our Spot and Kin solutions is the network capabilities. The Kin does not work on its own network. Instead, it uses our network of TU600 devices. With over 300,000 machines connected worldwide, your Kin will have many opportunities to connect to the network.

Complete the equipment tracking circle with Kin.

If you’re interested in learning more about the Trackunit products and services, you can request a demo with one of our experts.

Never miss an insight. We’ll email you when new articles are published on this topic.