Software

Trackunit Go brings you all the data and insights necessary to make immediate fleet management decisions or find, diagnose, and attend assets in need of attention.

Act Faster.

Act Anywhere.

Trackunit Go is for the traveling technician, the fleet manager in the field, or anyone on the go. Trackunit Go provides access to machine insights in order to efficiently complete daily tasks regardless of where you are.

Have Your Entire Fleet at Your Fingertips

Perform effective fleet management and enable the technician to diagnose and perform first time fixes on assets on the go.

Perform basic, yet effective fleet management on the go

Save time by attending all machines in close proximity

Eliminate downtime with remote diagnostics for first-time fixes

Improve accuracy and speed by reporting on the spot

Features

Know Which Assets Near You Need Attention

See which machines require you to take action – sorted by location, criticality, or machine name.

Features

Report and Log Machine Issues on the Spot

Report issues and mark criticality levels on the go.

Features

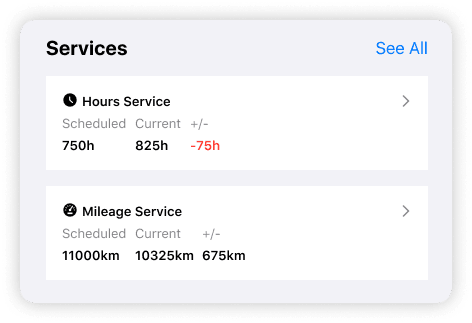

Overview of Machine Situation, Condition, and Context

The most important information presented in an easy-to-read overview that tells you all you need to know about your asset at a glance.

Features

Find and Get Directions to Your Machines

Trackunit Go provides you with the fastest route to where your equipment is currently located.

Want the Full Hands-on Experience?

Fill out the form to be contacted directly and get a hands-on demo of the product.

Thanks for Signing Up!

You will receive a confirmation email soon with your booking details.

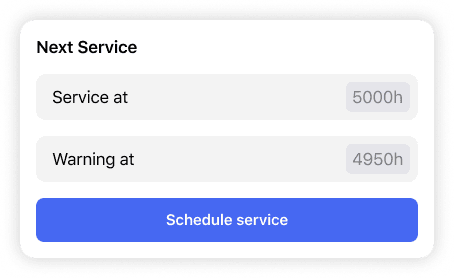

Features

Approve and Schedule Next Service on the Spot

Stay on top of your service schedule by approving and planning upcoming service procedures wherever you are.

“Trackunit Manager allows us to easily locate machines, set up geofencing, and use other alarms. It also makes machine handover effortless.”

Clemens Sieverding

Area Manager, Civil Engineering

Join the Best in Business

Join more than 7000 companies using Trackunit to keep their fleets in sight – even off site.