Overall, the market demand for augmenting construction equipment with new software capabilities, forces companies to re-balance organizational stability and dynamism.

Despite the demand for connectivity and its immediate reward constructions OEMs can do better – much better. We continue to see substantial differences in how well companies in construction make use of connectivity as a strategic component in their businesses.

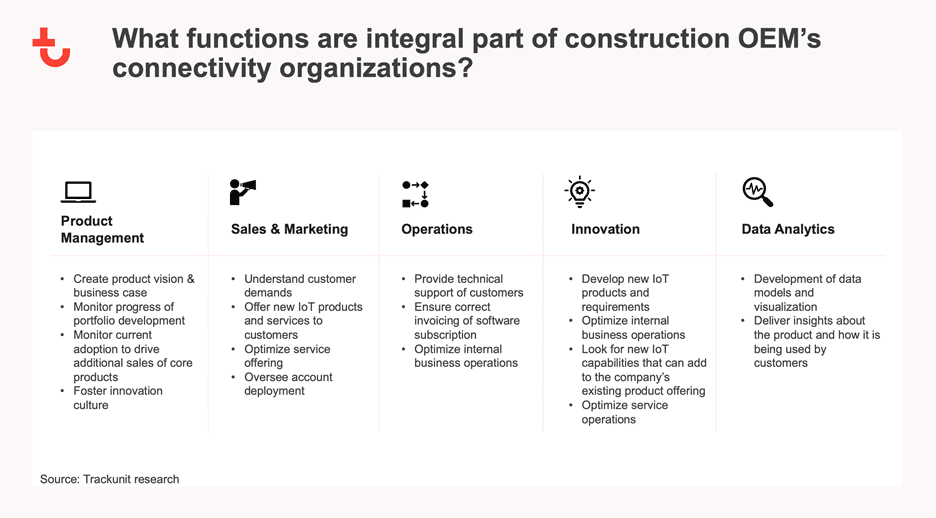

Our research based on input from 10 OEMs within the global top 30 show that successful OEMs exhibit the five trademarks described in this article: product management, sales and marketing, operations, innovation, data analytics.

The basic building block of the successful OEM are smaller fit-for-purpose teams with no room for spectators. The teams are comprised of individuals working on a shared task or networks of individuals working together in a coordinated way. With executive sponsorship, they have greater autonomy and accountability and move quicker than traditional functional areas.

Leading OEMs adopt a standpoint where connectivity is not being managed as a standalone product, or an optional add-on, but as an integral part of their service offering.

Backed by a solid business case, product managers are tasked with creating an exciting product vision for connectivity enabling them to champion it across the entire organization.

Depending on whether new services are built in-house or developed through a partnership, they oversee the partnership and internal development teams. They are responsible for keeping track of the entire connectivity portfolio across its life cycle. Owning a strategic change initiative requires them to both enable and foster innovation through culture and career development.

Sales and Marketing – deploying connectivity

Commercial functions are reimagining to both whom and how OEMs create value in the digital space. They are becoming intensely customer-focused and seek to meet diverse needs across the entire machine life cycle from rental to contractor. Large bids are not exclusively about the characteristics of the physical machines but increasingly about long term service capabilities enabled by digital products. This new type of demand requires organizations to focus their efforts on trainings and learning programs.

When separate service and connectivity commercial team is established, they work in a matrix-like structure with existing key account managers across the company and act as subject matter experts. After successful sales processes, they oversee deployment activities and remain point of contacts.

Connectivity operations embodies all administrative and support related back-office activities. This provides the foundation for the products success. They streamline existing connectivity related processes, interfacing other functional areas of the organizations, as well as coordinate projects enabling legal concerns to be resolved.

Long established OEMs are well aware of the intricacies of invoicing.

Invoicing of software products, often based on monthly payments and different feature packages, however, pose new challenges and require different organizational capabilities from internal tools to processes.

As connectivity enables construction OEMs to tap into new areas of development, ideas can start to travel around in the organization in the form of internal proposals. Managing new service offerings, digital products ideas across production units, sales subsidiaries requires both structure and an open-minded approach from the connectivity department. Innovation managers are not only looking for new IoT capabilities that can add to the company’s existing product offering but also optimize service operations (e.g. field services, maintenance, staffing).

Connectivity can bring immense amount of new data into OEMs, but without understanding data it remains an untapped potential. Therefore, to increase their success, leading OEMs have established data science and analytics capabilities focusing on both data modelling and data visualization. Identifying patterns, forming hypotheses around root causes that deliver essential insights into C-level committee meeting for decision making.

Our research shows that most successful OEM’s connected machine organizations combine and exploit all five key areas. Every organization is unique and face their own unique situations – there is no single path to connectivity success. However, building competencies across the five key areas described in this article will increase the odds of a valuable outcome.

Never miss an insight. We’ll email you when new articles are published on this topic.